CavityTherm brochure

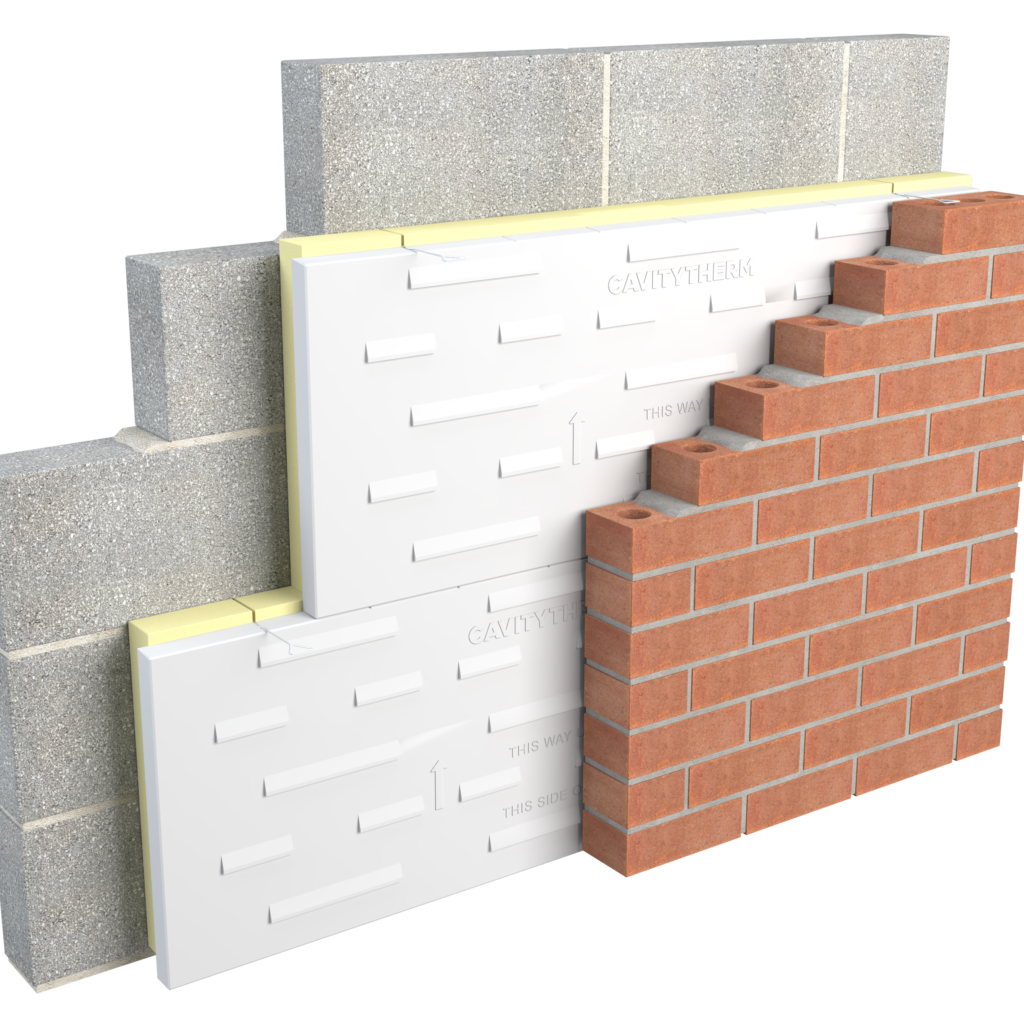

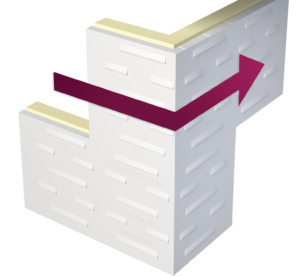

Built in Full Fill Wall Insulation

The Complete Cavity Wall System

Real performance on actual construction sites

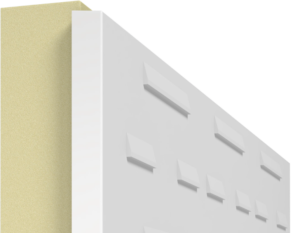

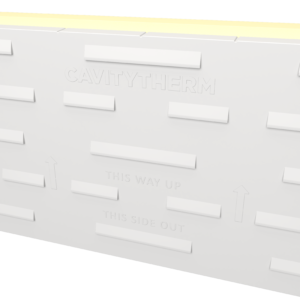

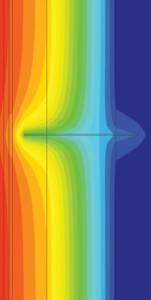

CavityTherm wall insulation board is a high performance composite board of enhanced PIR core with a lambda value of 0.021 W/mK. The boards have gas tight facings with one face bonded to a profiled HIPS skin during manufacture to provide a drainage plane.

Accessories

Do you have any questions? Our Technical Team provides technical services throughout our customer bases in Ireland & UK. Their…

Discover More

Do you have any questions? Our Technical Team provides technical services throughout our customer bases in Ireland & UK. Their…

Discover More

Element U-values (W/m²k) Floor 0.11 Cavity 0.16 Ceiling 0.12 Windows 1.40 Door 1.00 Thermal Bridging Y=0.04 Air Permeability 5 U-value Unit…

Discover MoreOur Technical Team provides technical services throughout our customer bases in Ireland & UK. Their experience and expertise has been built through our engagement and participation with the Irish construction industry for over 30 years.

Unilin Insulation reserves the right to change this information without notice. Unilin Insulation accepts no responsibility for errors or omissions on the website

Solutions you can trust.

Tel +44 (0) 371 222 1055

Stay informed of the latest developments with the Unilin Insulation mailing list

"*" indicates required fields

Have a look at our brochures, technical files and other documents